Apple’s upcoming 2.8 million square foot circular glass structure, officially called Campus 2 and also known as iSpaceship, could face further delays because it is now reportedly $2 billion over budget. Originally estimated to cost a whopping $3 billion to build, the budget for the new home to about 12,000 employees has now skyrocketed to nearly five billion dollars, Bloomberg Businessweek reports. Because of the risings construction costs, Apple’s Campus 2 could easily become an investor relations nightmare, the publication observes…

A life-size mock-up of the entrance to the future headquarters apparently depicts floor-to-ceiling glass and “a huge banner hanging from the ceiling with a photo of an iPhone.”

It’s being described as “clean, minimalist, and stunning – a four-story iPad.”

Reporter Peter Burrows, writing for Bloomberg Businessweek:

Since 2011, the budget for Apple’s Campus 2 has ballooned from less than $3 billion to nearly $5 billion, according to five people close to the project who were not authorized to speak on the record.

If their consensus estimate is accurate, Apple’s expansion would eclipse the $3.9 billion being spent on the new World Trade Center complex in New York, and the new office space would run more than $1,500 per square foot—three times the cost of many top-of-the-line downtown corporate towers.

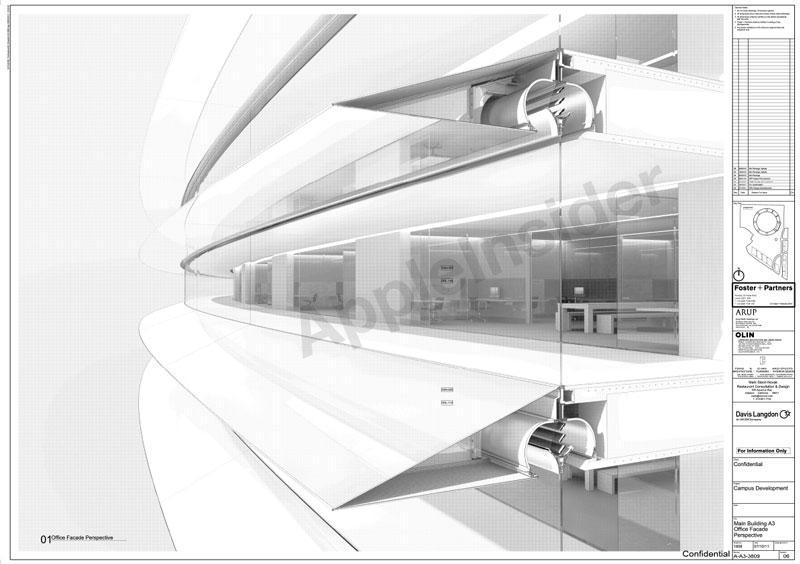

Construction plans call for six square kilometers of curved glass which requires special production techniques in order to prevent distortions. German maker Seele, which produces this curved glass, has had to double the size of its production facility to accommodate the project.

It gets better: the ceilings have to be polished concrete.

This specific requirement, which “left one person involved in the project speechless,” means contractors now have to cast the ceilings in molds on the floor and lift them into place rather than being cast in place.

Another interesting tidbit:

Arriving by truck will be thousands of prefabricated 26-foot-long modules in various configurations – bathrooms, utility closets, and banks of offices complete with carpets and window treatments.

Because the work is done in factories designed specifically for the purpose, the approach can yield far more precise construction and fewer hours of on-site labor – and potential savings on local union rates.

Last November, the project got delayed until 2016 over Apple’s and Steve Jobs’s legendary attention to detail. An Apple spokesperson said at the time that “we have approached this project with the same care and attention to detail we pay when designing any Apple product.”

Burrows suggests that Campus 2 could see further delays as lead architect Foster + Partners has now been tasked with cut $1 billion from the budget before proceeding.

Apple won’t break ground on the site until June, when the company is said to start tearing down the 26 buildings on the site, people in the know claim. “There’s so much dirt to be removed, excavating the site will take six months and require a continuous, 24-hour convoy of trucks, says a former Apple manager who heard a presentation from Foster’s firm,” Burrows writes.

That Apple is luring contractors by offering “only half the percentage of profit of some large deals” isn’t helping either.

According to sources who spoke to Burrows on the condition of anonymity, Apple’s fit and finish requirements are the big reason for the rising costs.

As with Apple’s products, Jobs wanted no seam, gap, or paintbrush stroke showing; every wall, floor, and even ceiling is to be polished to a supernatural smoothness.

Jobs was allegedly very exact in terms of gaps between surfaces, ordering they be no more than 1/32 of an inch. U.S. construction standards typically call for gap tolerances measuring about one-eighth of an inch.

All of the interior wood was to be harvested from a specific species of maple, and only the finer-quality “heartwood” at the center of the trees would be used, says one person briefed on the plan last year.

Apple’s late co-founder Steve Jobs had originally hoped to break ground in 2012 and to move in by the end of 2015.

Other Silicon Valley giants are following in Apple’s footsteps as the race is on who gets to build the most spectacular corporate structure. Back in February, graphics giant Nvidia announced a one million square feet triangle-shaped buildings featuring a nearly translucent glass roof.