Terry Gou, the CEO and chairman of Foxconn which assembles Apple’s iPhone and many other products, admitted in an interview with Reuters today that his company continues to face production hurdles meeting the massive iPhone 5 demand. It’s not surprising that the world’s largest contract manufacturer is coping with production issues.

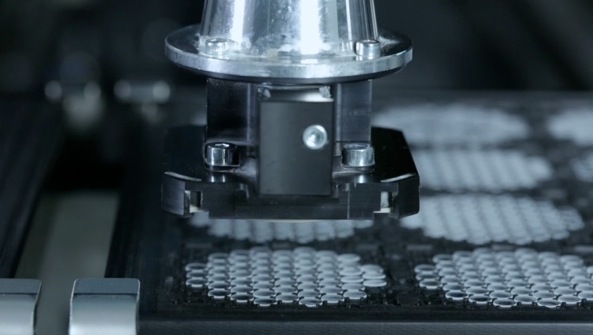

The company recently acknowledged that the iPhone 5 is “the most difficult device” it has ever assembled. In particular, the sophisticated handset with its in-cell display assembly technique and the excquisite Unibody chassis is proving challenging even for Foxconn to make in enough quantities. On top of that, Apple has tightened quality control following reports of teething issues with scratches and nicks from “normal” wear and tear…

Reuters quoted Gou who told reporters after a business forum:

It’s not easy to make the iPhones. We are falling short of meeting the huge demand.

Gou declined to comment on rumors that Foxconn International Holdings had taken on some production. He also told The Wall Street Journal that “market demand is very strong, but we just can’t really fulfill Apple’s requests”.

Foxconn is shipping “far fewer” units than expected, Gou noted, blaming production woes on the device’s precise design, but stopped short of detailing those. He also declined to say how long it will take for those issues to be solved.

The difficult iPhone 5 manufacturing process even spurred a massive brawl between workers and management at Foxconn’s Zhengzhou plant. At press time, the US online store showed a 3-4 week wait for iPhone 5 orders.

As if all of the above wasn’t enough, Sharp, a supplier of in-cell display panels for the iPhone 5, has enough problems of its own. The news gathering organization in another report suggested Apple should offer “financial incentives” to help save Sharp from going bankrupt.

Sharp lost a whopping $1.3 billion in early 2012 and is facing another $2.3 billion due in 2013. It is now in the midst of a restructuring plan involving layoffs and pay cuts in an attempt to prevent a sell off of its buildings and factories to pay off creditors.

Losing that potential lifeline from Foxconn was another setback.

As our own Cody Lee reported yesterday, Sharp is now hoping that Apple would come to the rescue and today’s post by independent analyst Horace Dediu suggests that the iPhone maker may have poured as much as $2 billion into Sharp’s production facilities, presumably in exchange for both continuity of supply and a balanced supplier base (offsetting Samsung, another Apple supplier).

So, problems with display panel supply on Sharp’s part coupled with complicated assembly process continue to plague Apple as the company copes with high iPhone 5 demand.

The company sold out of initial stock during first 24 hours of India launch. The handset is currently available in 31 countries. Apple is planning to roll out the iPhone 5 in China and a total of hundred markets across 240 carriers by year’s end.

Did you already purchasedyours?

Mine’s still in the queue.