Taiwan Semiconductor Manufacturing Company (TSMC), the world’s leading chip foundry, is reportedly planning to double down on its plans for chip factories in the United States.

STORY HIGHLIGHTS:

- TSMC plans to build six chip plants at the Arizona site.

- New plants would churn out three-nanometer chips.

- The three-nanometer plant would cost $23-25 billion to build.

TSMC doubling down on US chip plants

TSMC previously said it would pump $10 billion to $12 billion into a chip factory in Phoenix that could be the first of up to six planned plants at the site. And now, TSMC is considering pouring “tens of billions of dollars more” into sophisticated chip plants in Arizona to help the world cope with the global chip shortage that’s expected to last throughout 2022.

→ How to boot Apple silicon Macs into macOS Recovery

Reuters has the story:

Company officials are debating whether the next plant should be a more advanced facility that can make chips with so-called three-nanometer chipmaking technology compared to the slower, less-efficient five-nanometer technology used for the first factory. Officials have also sketched out plans for TSMC to make next-generation two-nanometer and smaller chips as the Phoenix campus is built out over the next ten to fifteen years.

The more advanced 3-nanometer plant could cost $23 billion to $25 billion, by the way.

TSMC’s first Arizona factory will be relatively small, with a projected output of 20,000 wafers—12-inch silicon discs that can each contain thousands of chips per month. By contrast, TSMC’s so-called gigafabs in Taiwan can produce 100,000 wafers per month.

And this:

TSMC leaders are taking a long view, starting with mature technology and ramping up volume while gradually introducing the most advanced processes.

TSMC earlier warned investors that the global chip shortage that’s hurting technology companies the most won’t be resolved anytime soon, continuing instead well into 2022.

TSMC counts Apple along with many other technology companies as its client.

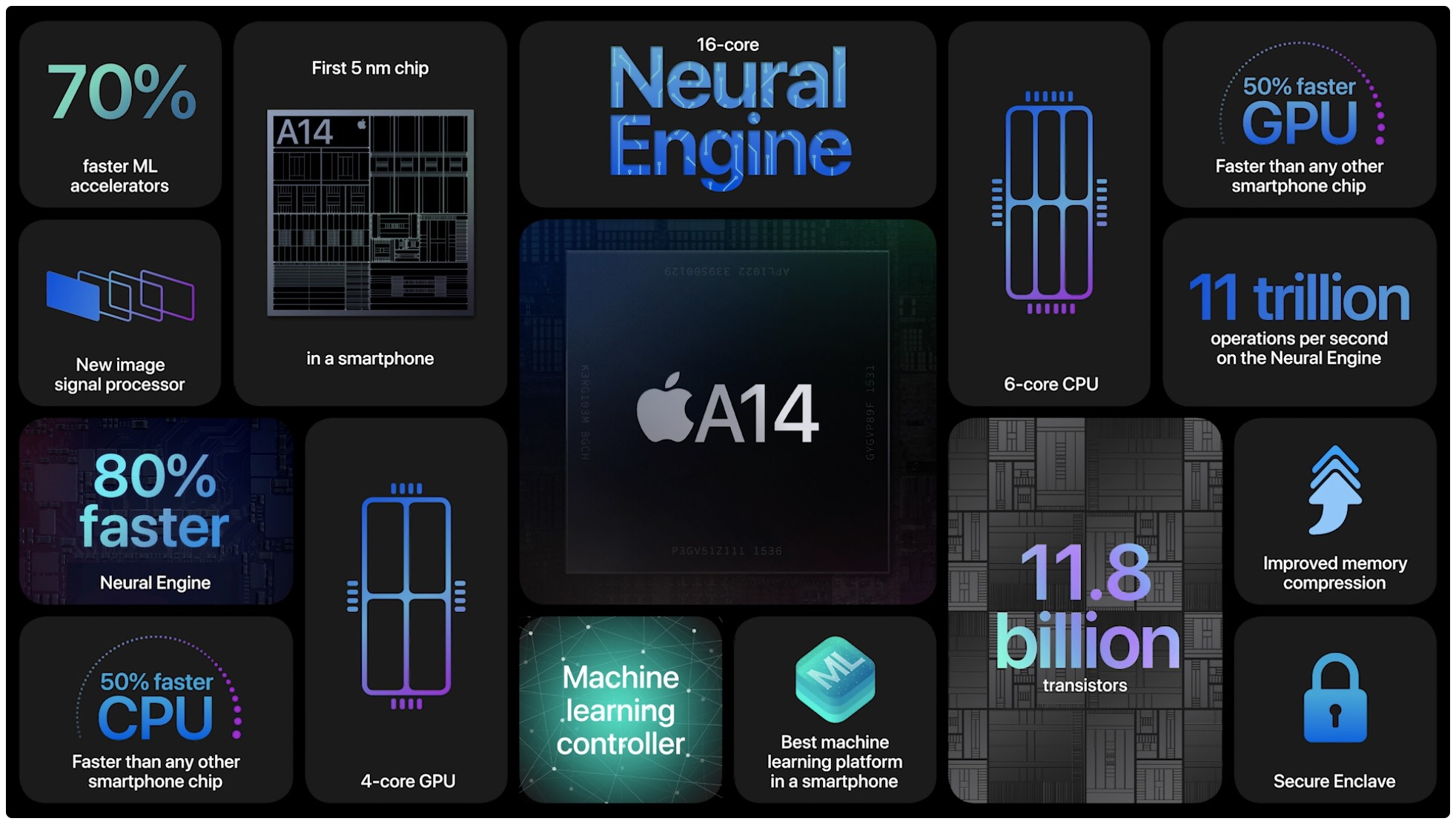

The independent semiconductor foundry has been churning out Apple-designed processors for iPhones, iPads and, recently, Macs for years now following Apple’s legal issues with Samsung.

The Galaxy maker used to be an exclusive manufacturer of Apple chips.

What’s the story with the global chip shortage?

The global shortage of semiconductors is blamed on remote work due to the coronavirus. Because folks weren’t spending their disposable income on traveling and going out, they instead upgraded their home electronics and bought entertainment devices to kill time.

The reason the semiconductor industry couldn’t respond to such a substantial increase in demand is simple: it takes a billion dollars or more to build a sophisticated chip factory from scratch and about 12-24 months before it can start churning out chips en masse.

One of the semiconductors that technology companies are finding increasingly hard to procure are microcontroller chips, typically found in almost every electronic device. The automobile industry was among the first to scale back its build plans due to the lack of chips.

Big-name technology companies also suffered a blow. Apple has already delayed some iPad and Mac production over the chip shortage, estimating a revenue hit of up to $4 billion in the current quarter as a result of the situation. But it’s not just Apple, though.

Gamers have been unable to buy the latest Nvidia graphics cards and Sony recently went on record, admitting that PlayStation 5 demand will outstrip supply throughout 2021.