The iPhone 5 is made with a level of precision you’d expect from a finely crafted watch, not a smartphone, says Apple’s marketing collateral. It ain’t just marketing talk. From these gorgeous shots to hands-on reports, everyone seems to agree that Apple has outdone itself with this year’s iPhone in terms of shininess and smoothness.

In order to avoid being leapfrogged by competition (the Galaxy S III feels pretty solid in one’s hand, doesn’t it?), Apple really upped the ante on build quality, traditionally its area of expertise. The manufacturing precision and craftsmanship that go into mass-producing these new iPhones is enough to give any gadget maker a pause.

From the handset’s lightly textured back to its highly polished chamfered edge with a nice sheen to it, Apple felt so confident in its manufacturing prowess that the company saw fit to brag about the unique production techniques it developed itself in order to build this phone…

Jony Ive, Apple’s SVP of Industrial Design, shed more light on the iPhone 5 production process in Apple’s presentation video.

Is it just me or did Ive put on a few pounds?

He said:

To create the new iPhone, we began with the design that we really loved. But to build it, to implement it – we had to look way beyond what we knew to be possible.

It took all of our learning, our best thinking, to realize something so simple, so clear and yet so truly extraordinary.

In order to build a product with this level of fit and finish and manufacturing sophistication, Apple had to develop production processes that Ive says are its “most complex and ambitious”.

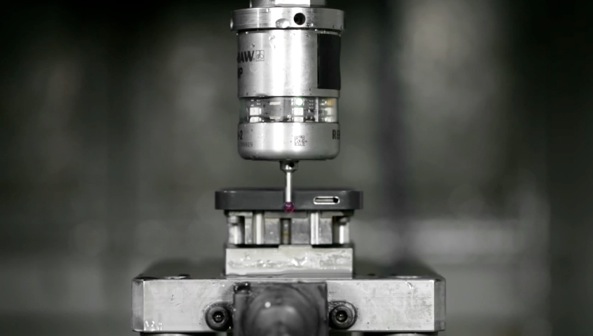

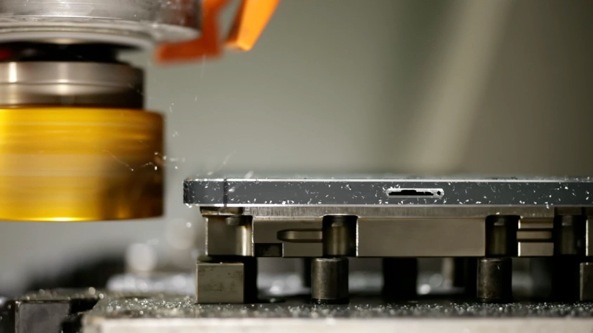

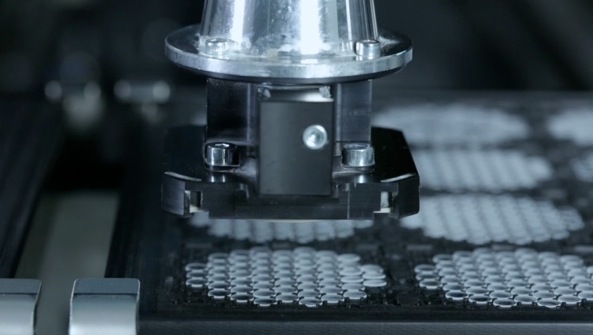

Take the iPhone’s Unibody enclosure and the mirror-like finish of its diamond-cut beveled edge.

Starting with the aluminum, we machine all of the surfaces of the enclosure.

We then polish and texture them.

We then use crystal and diamonds to cut the chamfers.

The end result: the near-mirror finish of the iPhone’s beveled edge.

The two-tone metallic backplate?

According to Apple:

The back of iPhone 5 is made of anodized 6000 series aluminum — the same material used in Apple notebooks — with inlays along the top and bottom made of ceramic glass (on the white and silver model) or pigmented glass (on the black and slate model).

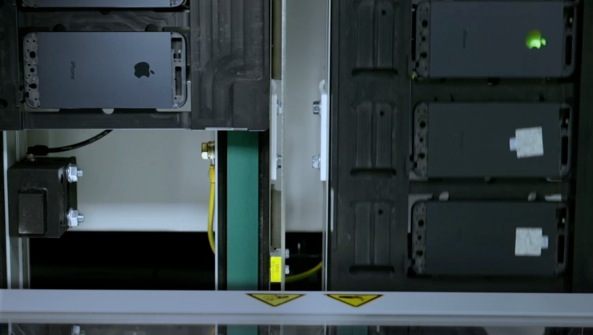

Production of the iPhone 5 inlays and fitting them together posed a whole new set of challenges as parts have to match perfectly. Otherwise, customers would notice and feel imperfections where the inlays meet.

So, how did Apple solve this challenge?

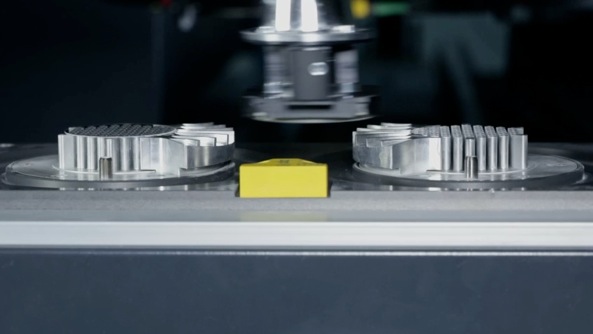

With the part on the conveyer…

…two high-powered cameras take pictures of the housing (and by ‘high-powered’ Apple means a whopping 29-megapixels…

…and instantaneous analysis is done…

…and then the best match out of the possible 725 cuts is determined.

Having this many pieces seamlessly come together results in the manufacturing precision where the variances from one iPhone 5 to another are now measured in microns – that is, one-millionth of a meter.

The in-cell process for the Retina display on the iPhone 5?

Here’s from Apple:

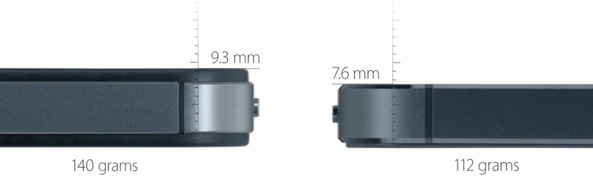

Making a thinner, lighter iPhone meant even the display had to be thinner. Apple engineers accomplished that by creating the first Retina display with integrated touch technology.

Which means instead of a separate layer of touch electrodes between display pixels, the pixels do double duty — acting as touch-sensing electrodes while displaying the image at the same time.

With one less layer between you and what you see on iPhone 5, you experience more clarity than ever before. All on a display that’s 30 percent thinner than before.

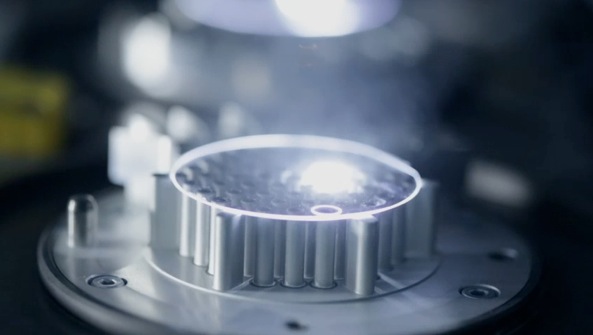

Yet another example: sapphire lens cover on the iSight camera.

Why sapphire?

Because sapphire is thinner and more durable than the cover glass on your iPhone 4/4S and because keeping optics in pristine condition is crucial for camera performance.

Here, a few snaps of the sapphire lens cover production.

By the way, hardness of sapphire crystal is second only to diamond (on the scale of transparent materials), which means that the surface of the lens on your iPhone 5 is far less likely to scratch.

But why agonize over such mundane things many won’t appreciate fully?

I mean, it’s just a phone, right?

We believe that going to such extreme lengths is the only way that we can deliver this level of quality.

We’ve developed manufacturing processes that are our most complex and ambitious. Never before have we built a product with this extraordinary level of fit and finish.

Fit and finish, materials and manufacturing processes are Jony Ive’s life.

But what’s in it for us, the consumers?

These techniques create a dramatic distinction between the product’s lightly textured back and its highly polished chamfered edge.

Most people don’t ever think about the difficulties Apple faced to make possible that smooth feel to the iPhone 5 in your hand.

To me, this obviously means Apple did a terrific job. People only pay notice of build quality when they pick up a crappy handset with ugly design and plasticky feel to it.

That’s when I begin to ask rhetorical questions, like “gee, they did this high-powered handset with a massive display and I can still hear the plastic cracking in my hand?”

Wrapping up, what makes the iPhone 5 so unique from manufacturing standpoint “is how it feels in your hand: the materials is being made with, the remarkable precision with which is being built”.

Bottom line: no details is too small and everything matters in an Apple product.

If you’re eager to learn even more about the iPhone 5 production process, Apple’s web site is your friend.

And no, it’s not about the looks.

Design is how it works.

So, materials and build quality…

Would you say this is something you take into consideration when choosing a smartphone?