Multiple production glitches early in the manufacturing process this summer could result in extended supply shortfalls and shipping delays for iPhone 8, with contract manufacturer Foxconn Technology Group now offering bonuses to employees who can bring in new hires.

That’s according to a new report Thursday by The Wall Street Journal.

For context, Apple’s partners normally kick off production by July.

Citing people familiar with the situation, the report said:

The production glitches led to a setback of about a month in the manufacturing timetable. Foxconn Technology Group, the Apple contractor that assembles iPhones, has been ramping up production at its manufacturing complex in Zhengzhou, China. The company is paying bonuses to employees who can help bring new hires on board at its Zhengzhou plant, which Foxconn said in June employs about 250,000 people.

The OLED assembly process requires “more steps and more layers of adhesive” than with other phones because iPhone 8 also has an additional 3D Touch sensor layer that Samsung’s devices lack, which has contributed to production woes.

Here’s an excerpt from the report:

Unlike the OLED display module in Samsung’s own smartphones, in which the display and touch panel are integrated, iPhone’s display module has the touch panel outside of the display, according to a person familiar with the technology.

The iPhone manufacturing process requires more steps and more layers of adhesive and protective film than are involved in Samsung’s manufacturing process, the person familiar with the process said, creating a greater risk of manufacturing error.

The article reiterates previous reports which said that the OLED iPhone could debut with a possible $1,000 base price due to increased component costs. KGI Securities analyst Ming-Chi Kuo says Samsung has leveraged its dominant position as the world’s leading OLED panel producer with a 90+ percent market share to charge a premium for OLEDs.

The analyst pegs OLED unit cost at $120-$130 per unit versus the $45-$55 unit cost of LCD panels. iPhone 8 display modules are being produced in Vietnam by a Samsung affiliate.

The South Korean company is the sole supplier of OLEDs for iPhone 8, but Apple is apparently working to add LG Display as a second supplier by 2019.

On top of that, the report continued, Apple was hopeful until the last minute that it could embedded a fingerprint sensor underneath the display, but it “proved difficult” as in-screen Touch ID technology just isn’t mature enough yet.

As a result, the Cupertino company has ditched the solution in favor of an old-fashioned password and a new 3D facial scanning feature.

Rear Touch ID, you say?

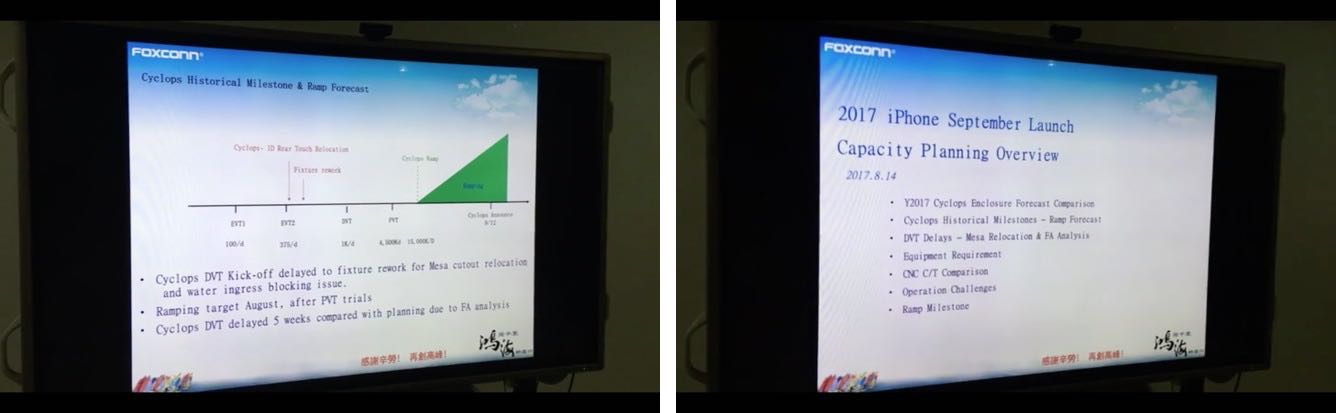

A sketchy video of an alleged Foxconn presentation slides, dated August 14, indeed indicates that the Cupertino company was testing a rear-facing Touch ID sensor on iPhone 8. Consistent with today’s report by The Wall Street Journal, these slides suggests that Foxconn was not expecting to ramp up iPhone 8 production until August.

The presentation slides reference “Mesa”—which is Apple’s code-name for Touch ID—and include text snippets like “Cyclops—ID Rear Touch Relocation” and “Cyclops DVT Kick-off delayed to fixture rework for Mesa cutout relocation and water ingress blocking issue.”

”Cyclops” is Foxconn’s code-name for iPhone 8.

The now-removed video was found on China’s Badu and reposted by leaker Benjamin Geskin.

As a result of the aforementioned manufacturing glitches, precious time was lost and production was put back by about a month. In spite of delayed production, the article claims that iPhone 8 will ship alongside LCD-based iPhone 7s/Plus models on September 22.

Apple has sent out invites for the September 12 unveiling at the Steve Jobs Theater and informed carriers that pre-orders for the new iPhones will kick off three days later.