After reporting that Apple supplier Taiwan Semiconductor Manufacturing Company (TSMC) will share next year’s production of A8 chips with Samsung, the sometimes-reliable Taiwanese publication, DigiTimes, today said that the world’s largest independent semiconductor foundry will account for more than half of total A9 chip output in 2015, with only one-third of chip manufacture to be handled by Samsung.

The South Korea-based Samsung up until this year used to exclusively produce Apple designed mobile processors for the iPhone, iPod touch and iPad devices, but Apple’s been looking to distance itself from the company in order to prevent Samsung engineers from getting an early glimpse into its upcoming chip tech…

According to industry sources who spoke to DigiTimes, Apple and Samsung Electronics have allegedly signed a deal to produce the upcoming A9 chips on the sophisticated 14/16-nanomenter FinFET processes.

Rival TSMC, however, will be responsible for as much as 70 percent of total A9 chip production, the article has it.

Samsung will use its 14nm FinFET process to manufacture a portion of the A-series chips for Apple’s 2015 iPhone series, and the remainder of the chips will be built using TSMC’s 16nm FinFET technology, the sources indicated.

TSMC should land 60-70 percent of Apple’s total 14/16nm chip orders, with the remaining 30-40 percent to be taken over by Samsung, the sources said.

The article goes on to warn of a possibility that TSMC and Samsung could also equally share Apple’s chip orders for 2014.

DigiTimes previously reported that TSMC has now become the main foundry for next year’s A8 chips, to be fabbed on the 20-nanomenter process. The A8 is expected to power the next-generation iPhone, likely the next year’s iPhone 6.

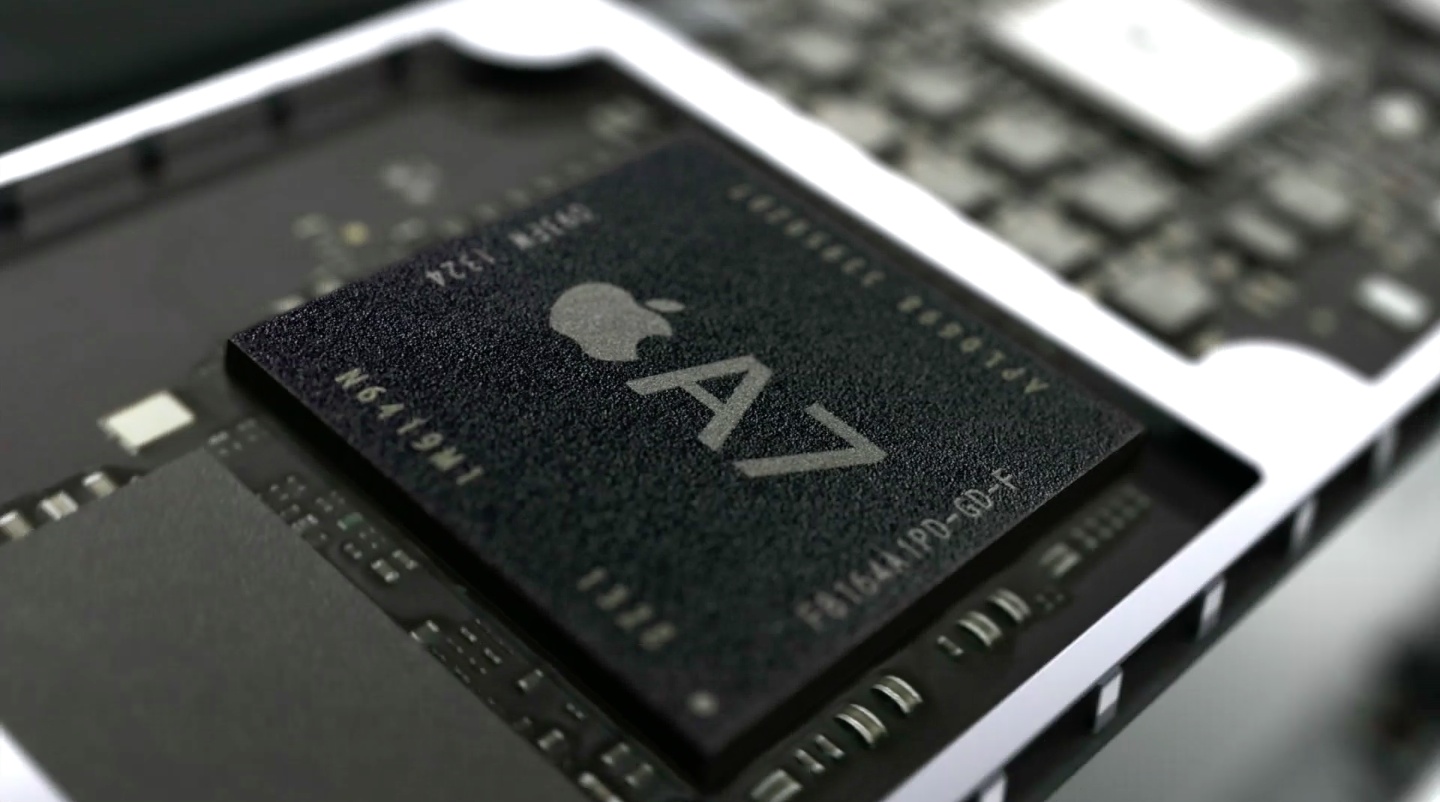

The current-generation 64-bit A7 system-on-a-chip package that powers the iPad Air, the iPhone 5s and the iPad mini with Retina display is being built using Samsung’s 28-nanometer high-κ metal gate (HKMG) process technology.

TSMC CEO Mark Liu previously said his company’s 16-nanometer fab would go online by the end of 2014. At the same time, Samsung confirmed its more advanced 14-nanometer process will be up and running by the end of next year as well.

The Wall Street Journal wrote back in July that Apple had inked a deal with Samsung to manufacture the 14-nanometer A9 chips, with the financial newspaper’s June report asserting that Samsung would not be the sole supplier of the chips and would share orders with rival TSMC.

Apple has been looking to decrease its dependence on Samsung ever since its legal wrangling with the Galaxy maker over its wholesale copying of patented iPhone technology, which has turned the supplier relationship into bitter rivalry.

However, the move to TSMC would represent a huge brain transplant as FinFET technology uses entirely new three-dimensional transistors and only Intel at the moment has the technology to make these chips in commercial quantities.

Also, keep in mind that Samsung is the world’s second-largest chip supplier, after Intel.

TSMC, though the world’s largest independent semiconductor foundry, thus far has lacked the ability to meet Apple’s exacting standards and pricing, let alone match the iPhone maker’s huge and growing volume requirements, measured in hundreds of millions of mobile processors each year.

Matter of fact, AllThingsD recently confirmed that Samsung in an effort to match Apple’s growing needs turned to GlobalFoundries for what is known as “flex capacity,” an industry practice under which a chip manufacturer pays to occasionally use another company’s factories when demand on their own factory is running higher than they would like, and they need a little help.