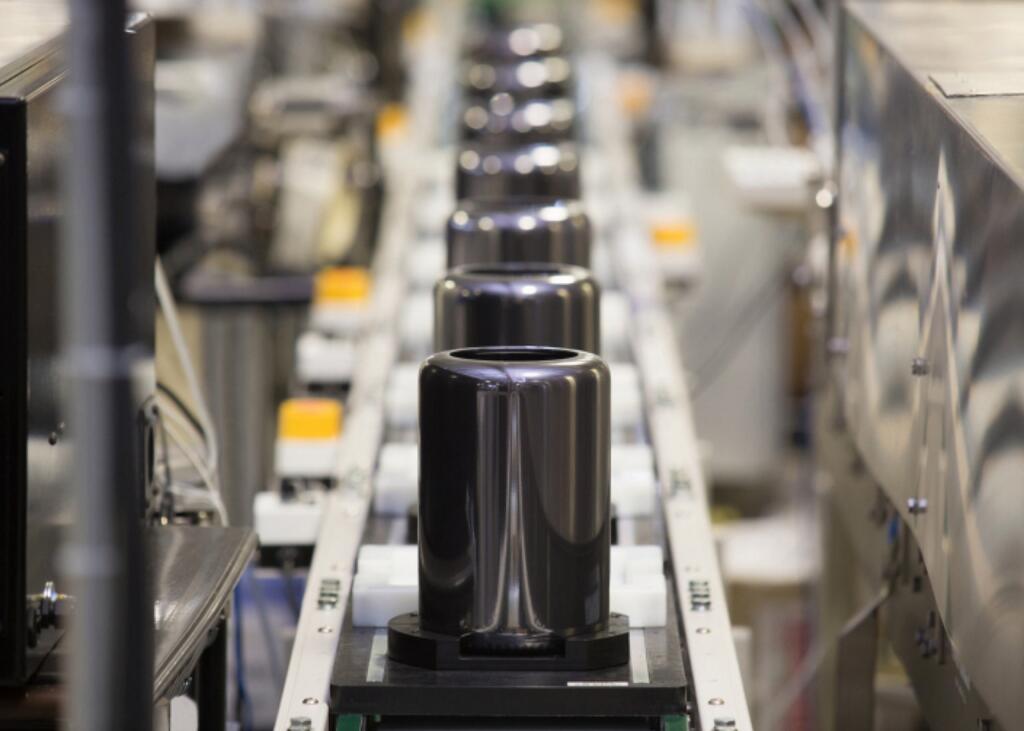

The vast majority of iPhones and Macs are manufactured and assembled in China so when Apple in 2012 announced that its partner Flextronics would produce the Mac Pro chassis at its manufacturing plant on the outskirts of Austin, Texas, some people were expectedly skeptical.

The company shifted most of its domestic hardware production to foreign manufacturing in 2004, a move led by the company’s then operations chief Tim Cook.

According to a New York Times story published this morning, despite the US-China trade war and Trump’s calls for Apple and other major US technology companies to bring their manufacturing closer home, that’s unlikely to happen.

A tale of a tiny screw illustrates why.

In 2012, Apple’s chief executive, Timothy D. Cook, went on prime-time television to announce that Apple would make a Mac computer in the United States. It would be the first Apple product in years to be manufactured by American workers, and the top-of-the-line Mac Pro would come with an unusual inscription: ‘Assembled in USA.’

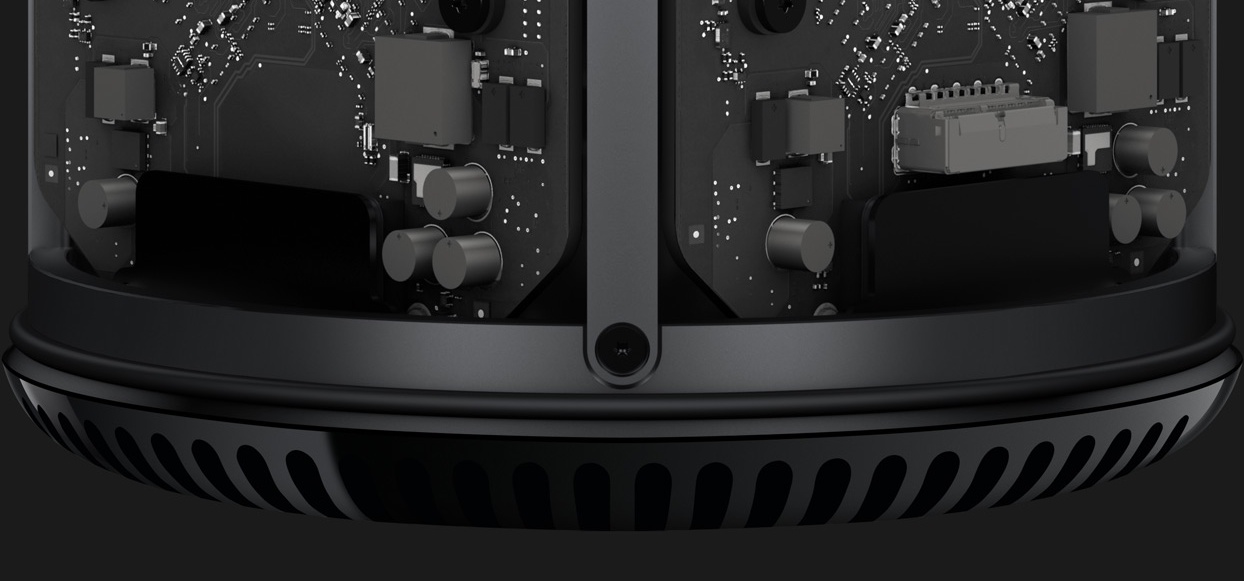

But when Apple began making the $3,000 computer in Austin, Texas, it struggled to find enough screws, according to three people who worked on the project and spoke on the condition of anonymity because of confidentiality agreements.

You would think that finding enough screws shouldn’t be a problem for an industrial nation like the United States, but nothing can touch huge manufacturing plants in China that can produce vast quantities of custom screws on short notice.

Tests of new versions of the computer were hamstrung because a 20-employee machine shop that Apple’s manufacturing contractor was relying on could produce at most 1,000 screws a day.

The screw shortage was one of several problems that postponed sales of the computer for months, the people who worked on the project said. By the time the computer was ready for mass production, Apple had ordered screws from China.

Apple, like other major technology players, has simply realized that no country is able to match China’s combination of scale, skills, infrastructure and cost.

The minimum wage in Zhengzhou, China, home of the world’s biggest iPhone factory, is roughly $2.10 an hour, including benefits. Apple said the starting pay for workers assembling its products there is about $3.15 an hour. Compensation for similar jobs in the United States is significantly higher.

And that, my friends, is what you get with the current system that priorities maximizing shareholder value at at all cost—even to the detriment of the American worker.

A former Apple manager said:

The Flextronics team had also been far smaller than what he typically found on similar Apple projects in China. It was unclear exactly why the project was understaffed, the manager said, speculating that it was because American workers were more expensive.

The manager said similar Apple jobs in China would include a roomful of people working to ensure that all materials were in place for production. In Texas, it was one worker, who often seemed overwhelmed, the manager said.

As a result, materials were regularly out of place or late, contributing to delays. Another frustration with manufacturing in Texas: American workers won’t work around the clock. Chinese factories have shifts working at all hours, if necessary, and workers are sometimes even roused from their sleep to meet production goals.

Needless to say, that was not an option in Texas.

The report adds that the final assembly is the most labor-intensive part of building technology products, and its location often determines a product’s country of origin for tariffs.

Apple is currently exploring ways to assemble some of its products in India and Vietnam. In India, for instance, it recently began building the iPhone 6s handsets (in addition to “Assembled in India” iPhone SE units), according to a recent report in The Economic Times.

TUTORIAL: How to bypass article paywalls

While Apple now produces two iPhone models locally in India, that’s a far cry from those busy factories in China that churn out millions of Apple gadgets every month.

Put simply, those manufacturing jobs are never coming back home due to not only costs involved but also the technical skills, expertise and China’s vast supply chain.

“In the US, you could have a meeting of tooling engineers and I’m not sure we could fill the room,” Tim Cook said in 2017. “In China, you could fill multiple football fields.”

In December, Apple said it would add up to 15,000 workers in Austin, just miles from the Mac Pro plant. However, none of the new jobs are expected to be in manufacturing.

And that’s the reality of it, really.

What do you make of this report?

Let us know by leaving your thoughts in the comment section.