U.S. President-elect Donald Trump repeatedly said during his campaign that he would force domestic technology companies like Apple to build its “computers and things” in the United States.

One time, he even openly called for boycotting Apple products unless the company doesn’t bring back manufacturing jobs it had outsourced to China many, many, many years ago.

Japanese outlet Nikkei is reporting today that iPhone contract manufactures Foxconn and Pegatron were approached recently by the Cupertino firm regarding the possibility of establishing iPhone manufactories in the United States.

“Apple asked both Foxconn and Pegatron, the two iPhone assemblers, in June to look into making iPhones in the U.S.,” a source said. “Foxconn complied, while Pegatron declined to formulate such a plan due to cost concerns.”

Another source said Asian supply chain thinks that U.S. President-elect might push Apple to make “a certain number of iPhone components” at home. Yet another industry source said that it’s not easy to make iPhones in America “unless the U.S. government subsidizes local companies for producing domestically.”

iPhone chip maker TSMC may also establish U.S. plants, but that firm’s made it very clear that it’d be much more pricier to make iPhone chips outside of Taiwan.

Foxconn and Pegatron manufacture more than 200 million iPhones annually.

Some components for Macs, but not iPhones, are currently being built in the U.S. For instance, Apple supplier Flextronics has been producing Mac Pro enclosures at a plant in Austin, Texas since 2013. And in 2012, Foxconn established an iMac assembly line in the same state. Sharp recently hinted that it might establish a U.S. facility to build OLED panels for future iPhones “if our key customer demands us to manufacture in the U.S.”

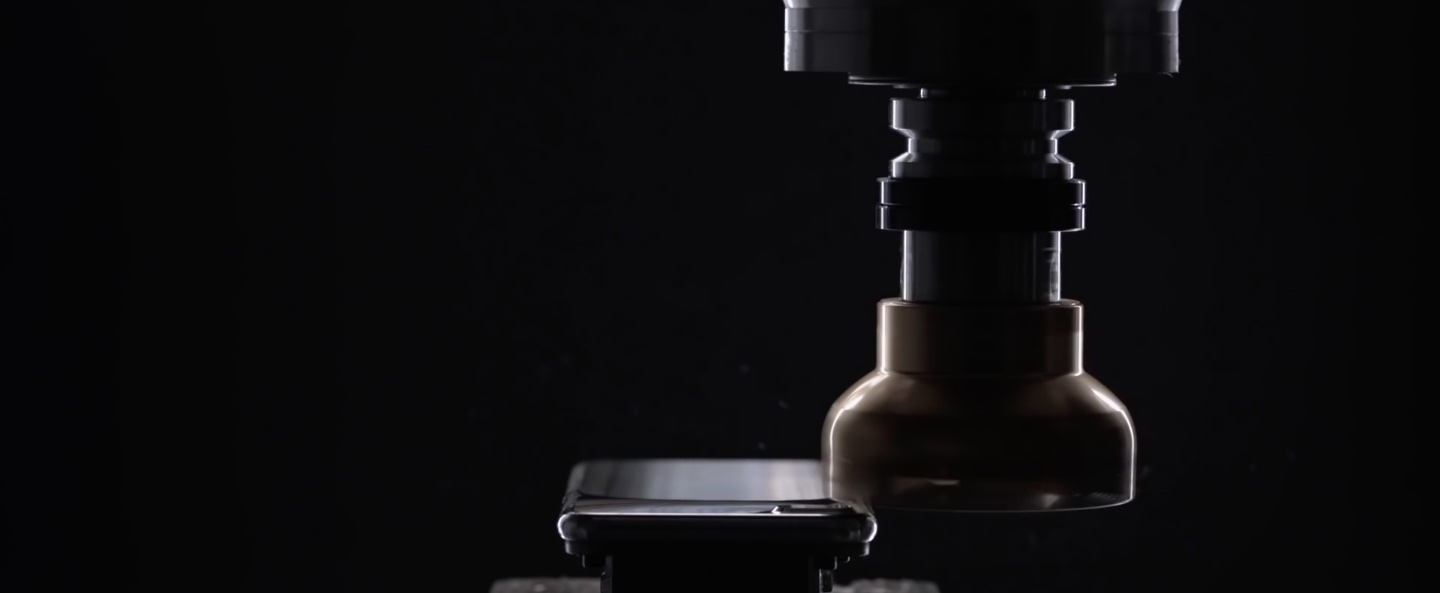

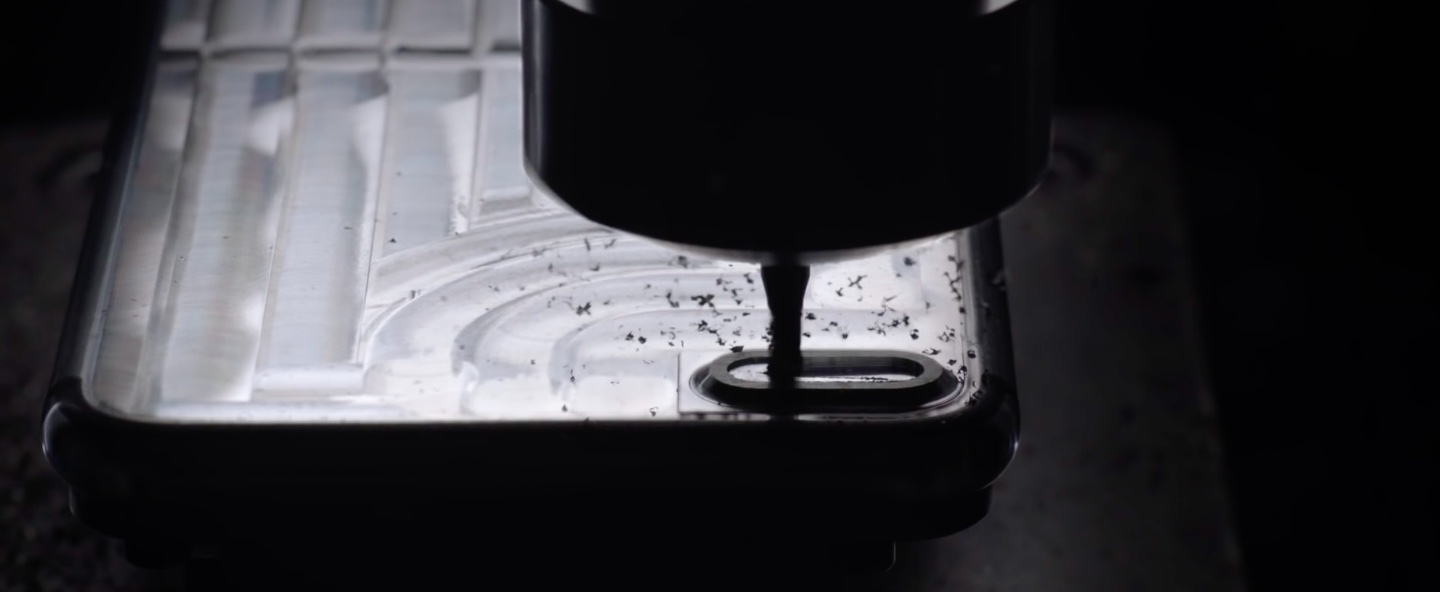

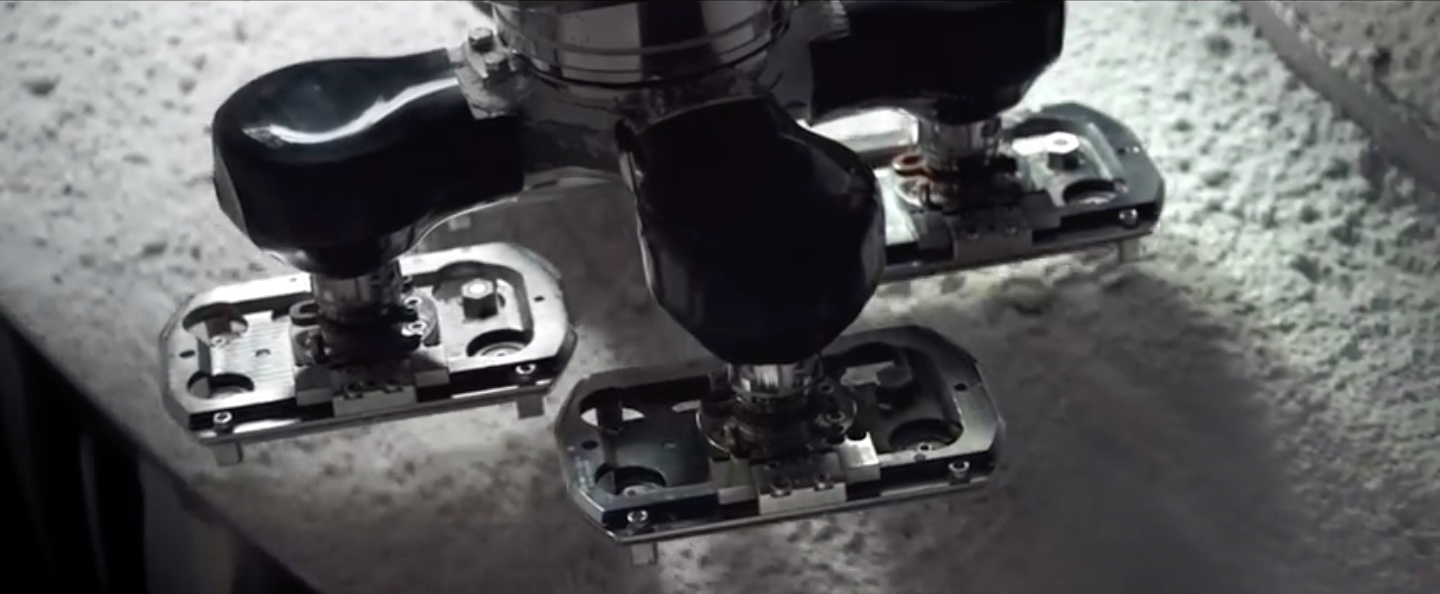

Here are some of the complex manufacturing steps involved in producing the pristine-quality fit and finish of the iPhone 7’s Jet Black colorway.

https://www.youtube.com/watch?v=sbios0u2Px8

Bringing manufacturing jobs back home may be easier said than done, with Apple’s boss having been repeatedly saying that those jobs have been long lost to China.

With a typical monthly wage of a Foxconn assembly line worker hovering slightly above $200, Apple would need to persuade its shareholders to cope with diminishing returns on their investment due to increased labor and production costs stemming from hiring U.S. workers to assemble iPhones and other gadgets.

Indeed, Foxconn Chairman Terry Got had reportedly been “less enthusiastic” about moving iPhone production to the States due to an inevitable rise in production costs.

“Making iPhones in the U.S. means the cost will more than double,” the source said.

It was investors that pushed U.S. technology companies to outsource most of their production overseas in the first place. Chalk that up not only to this age globalization and free trade, but also to Wall Street’s greed and quest for ever-increasing profits at the expense of workers and their families, no matter the country where they happen to live.

“We’re going to get Apple to build their damn computers and things in this country instead of in other countries,” Trump said at Liberty University in Virginia in January. In March, Trump asked rhetorically, “How does it help us when they make it in China?,” during his Super Tuesday victory speech.

Chinese government warned that if the Trump administration goes ahead and starts a trade war with them, “U.S. auto and iPhone sales in China will suffer a setback.”

Be that as it may, the new administration is going to face an uphill battle in convincing corporations and their powerful investors that bringing those very low-paying jobs from China back to the United States would be in their best interest.

Tim Cook said on CBS’ 60 Minutes that it’d be next to impossible to move iPhone production back to the U.S. due to a lack of infrastructure and required skills.

“To make iPhones, there will need to be a cluster of suppliers in the same place, which the U.S. does not have at the moment,” he said. “Even if Trump imposes a 45 percent tariff, it is still possible that manufacturers will decide to continue production overseas as long as the costs together with the tariffs are lower than the amount they need to spend on building and running production lines in the U.S.”

According to U.S. think-tank Economic Policy Institute, America had lost a whopping five million manufacturing jobs between 2000 and 2014.

Source: Nikkei