Apple and Taiwan Semiconductor Manufacturing Company (TSMC) are developing a next-generation mobile chip that will make its debut in an upcoming iPad Pro revision next year.

The next iPad Pro rumored to run 7nm A11X Bionic chip with 8 CPU cores

Apple and Taiwan Semiconductor Manufacturing Company (TSMC) are developing a next-generation mobile chip that will make its debut in an upcoming iPad Pro revision next year.

Taiwan Semiconductor Manufacturing Company (TSMC), the world's largest contract chip maker, is in the early stage of development and testing of manufacturing processes in preparation for Apple's next-generation A12 chips for 2018 iPhones.

Taiwan Semiconductor Manufacturing Company (TSMC), the sole supplier of Apple's new A11 processor, recently kicked off mass production of the upcoming chip and last week leak aggregator SlashLeaks posted a pair of blurry images claiming to depict the new processor.

While market watchers are still unsure if Apple could manage to ramp up iPhone 8 production in time for a September launch, a report Friday from Taiwan's TechNews, quoted by DigiTimes, alleges that Taiwan Semiconductor Manufacturing Company (TSMC) has now kicked off volume production of the device's in-house designed A11 chip.

Taiwan Semiconductor Manufacturing Company (TSMC) has been exclusively fabricating Apple's in-house designed mobile chips for iOS devices since 2015 and the company has now reportedly accelerated its efforts to build seven-nanometer chips in 2018.

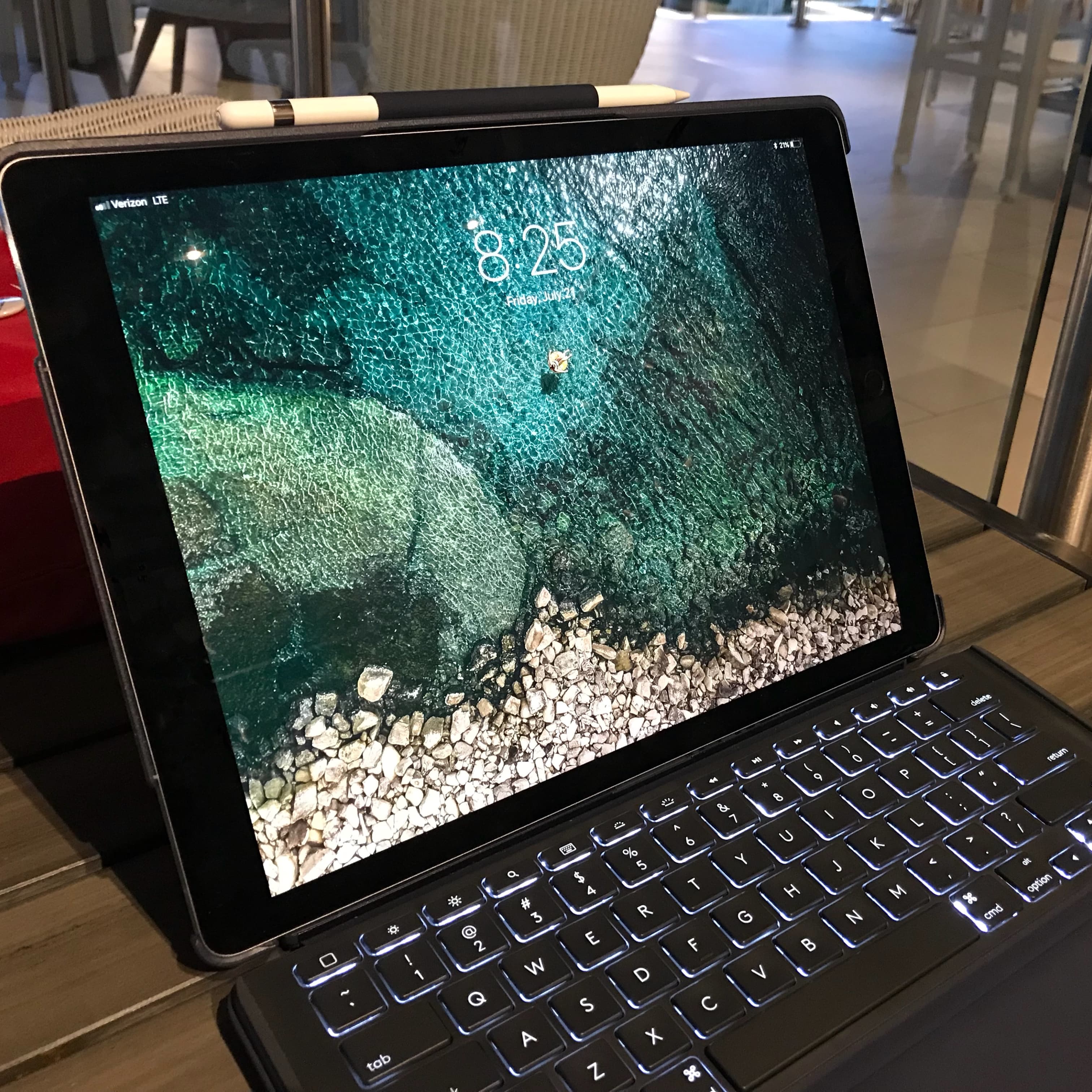

The in-house designed Apple A10X Fusion chip powering the new 12.9-inch iPad Pro and 10.5-inch iPad Pro models is being fabricated on a cutting-edge ten-nanometer process technology by Taiwan Semiconductor Manufacturing Company (TSMC).

Having analyzed the processor, TechInsights was able to confirm that it's the first TSMC-built ten-nanometer chip to show up in a consumer device.

It's not the world's first ten-nanometer silicon to appear in a smartphone: a Samsung or Qualcomm-designed processor powering Galaxy S8 is built on Samsung’s 10 nm LPE process.

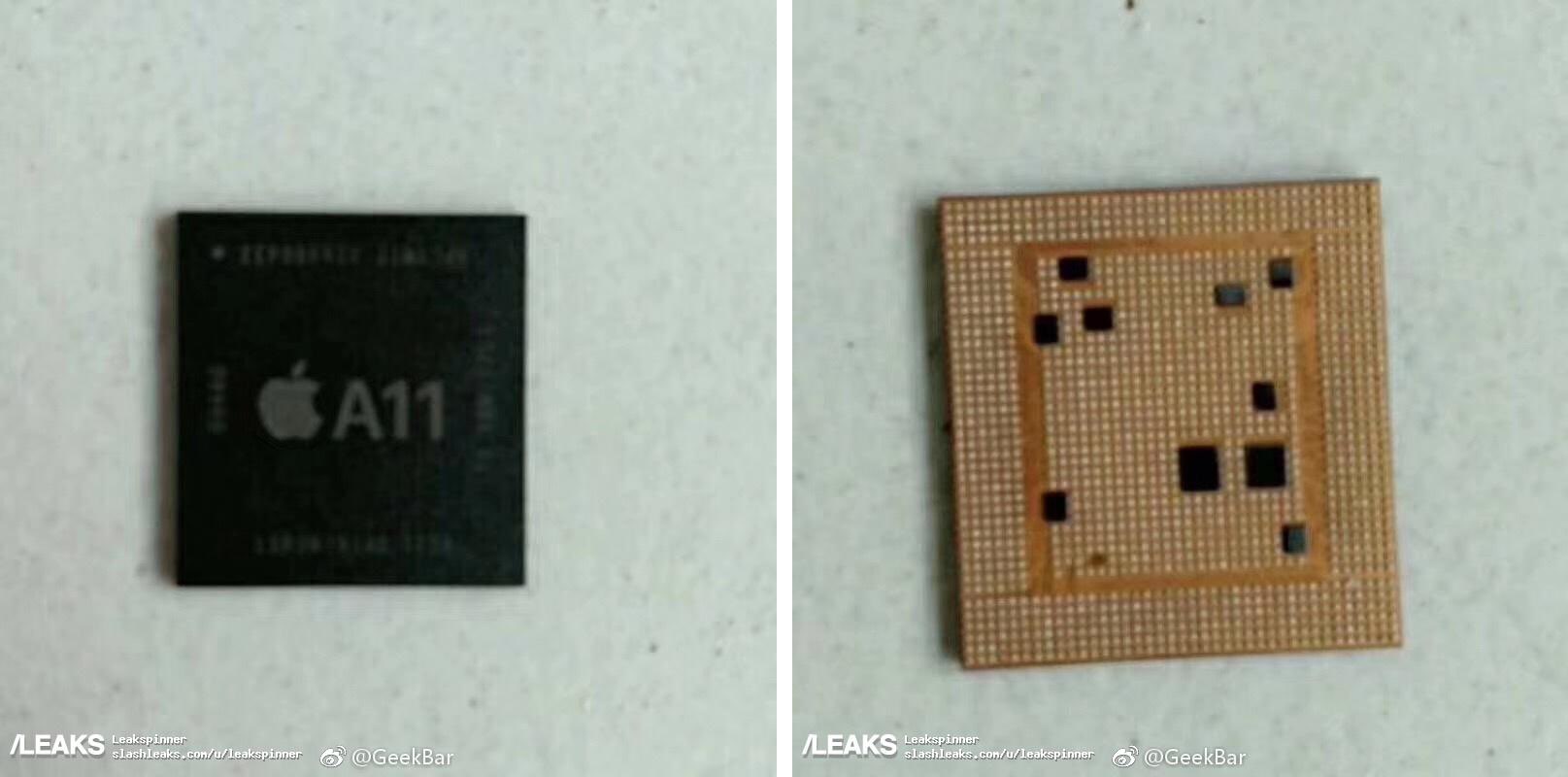

A detailed floorplan analysis of Apple's latest chip has revealed a die size of 96.4 mm2 versus the A9X which has a die size of 143.9 mm2 and is built on TSMC’s 16 FF-Turbo technology.

Despite its power, the A10X Fusion has the smallest die size for an iPad processor yet.

AnandTech says A10X Fusion's CPU clock speed is only marginally higher than A9X's, “and pretty much identical to A10”. Images of the chip's floorplan seen top of post and bottom reveal the chip's 12 GPU clusters on the left, along with the CPU cores to the right.

Chart via AnandTech.

“This is an impressive full node scale, when accounting for the extra CPU cores built into the A10X and extra IP blocks of the A10 vs. A9 family,” notes TechInsights.

AnandTech added:

Ultimately what this means is that in terms of design and features, A10X is relatively straightforward. It’s a proper pipecleaner product for a new process, and one that is geared to take full advantage of the die space savings as opposed to spending those savings on new features/transistors.

For those wondering, the GPU cores in the A10X Fusion chip appear to be the same Apple-customized PowerVR cores from Imagination Technologies, a British GPU designer.

As you may have heard, Apple is now developing on its own mobile GPUs to supplant Imagination-powered graphics for iOS devices.

A10X Fusion features thirty percent faster CPU performance and forty percent faster graphics compared to its predecessor, the A9X chip powering the original 12.9-inch iPad Pro.

Chip foundry Taiwan Semiconductor Manufacturing Company (TSMC), which counts Apple as its biggest client, is ready to move its cutting-edge seven-nanometer process technology to volume production in 2018.

According to DigiTimes, an improved version of TSMC's seven-nanometer process using extreme ultraviolet technology will be ready for volume production in 2018, according to company co-CEO CC Wei.

The firm's five-nanometer node is slated to enter risk production in 2019, Wei added.

TSMC currently makes A10 chips for iPhone 7 and is said to be exclusively churning out the upcoming Apple-designed A11 processors for iPhone 8 and other 2017 iOS devices.

TSMC in April reportedly began stockpiling A11 chips for 2017 iPhones.

The firm should step up its pace of inventory building from June onward, said industry sources.

iPhone 8's A11 system-on-a-chip should be built on TSMC's ten-nanometer process technology, yielding faster performance and lower power consumption.

The A11 Fusion chip inside iPhone 7 is being manufactured on TSMC's 16-nanometer node.

Apple is building a brand new chip dedicated to artificial intelligence and machine learning, Bloomberg said recently, but it's unclear if the new chip will make its way into iPhone 8.

Quarterly chip demand for iPhone is predicted to surpass 50 million units in the second half of this year as Apple begins to stockpile next-generation processors and other chips for 2017 iPhones, trade publication DigiTimes said Wednesday. Chip orders should hit a total of between 220 million and 230 million units between the end of the second quarter and the beginning of the third. This implies strong projected demand for the OLED-based iPhone 8 and the iterative LCD-based iPhone 7s and iPhone 7s Plus updates.

Apple's favorite chip foundry, Taiwan Semiconductor Manufacturing Company (TSMC), is about to kick off volume production of a new Apple-designed A11 chip widely expected to serve as the engine for new iOS devices this year, including an all-new iPhone 8 with an OLED display and the iterative iPhone 7s and iPhone 7s Plus with LCD screens.

iPhone and iPad silicon maker Taiwan Semiconductor Manufacturing Company Limited (TSMC) won't make the decision whether or not it would build a foundry fab in the United States until sometime in 2018, Reuters reported Monday. The firm hinted it might start building some of the chips in America.

TSMC, which exclusively churns out Apple-designed mobile processors for latest iPhone and iPads, won't make a definite decision on building a US plant this year because it would lose its "flexibility" if it made the move this year.

Semiconductor foundry Taiwan Semiconductor Manufacturing Company (TSMC) is kicking off commercial shipments of chips built on its new ten-nanometer process technology, ahead of iPhone 8, sources told Taiwanese trade publication DigiTimes. TSMC is building iPhone 7's A10 Fusion chip and is said to have landed an exclusive contract to manufacture processors for 2017 iPhone and iPad models.

As we reported this morning, iPhone manufacturer Foxconn and its Japanese subsidiary Sharp are considering setting up an $8 billion LCD panel production plant in the United States. According to another report, semiconductor maker Taiwan Semiconductor Manufacturing Company Limited (TSMC) has also expressed interest in taking advantage of business-friendly incentives proposed by incoming U.S. President Trump.

As a reminder, TSMC currently churns out Apple-designed silicon for latest iOS devices and is also said to have landed a lucrative contract to build next-generation A11 chips for future Phones and iPads.