Media reports about Scuffgate related to the widely reported quality-control issues with iPhone 5 manufacturing have subdued a bit as we head into the iPad mini press conference next Tuesday. That said, it’s a tad surprising Apple’s favorite contract manufacturer Foxconn would agitate spirits by explaining to The Wall Street Journal why the iPhone 5 is so difficult to manufacture.

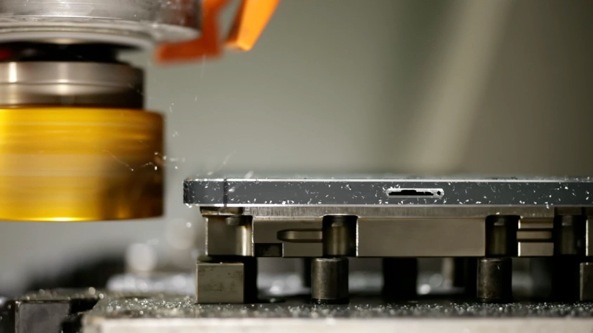

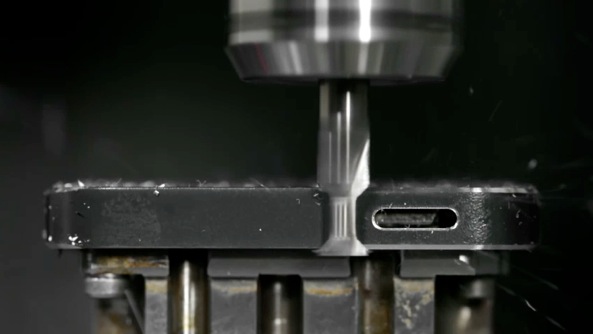

Apple’s phone, in Foxconn’s words, is “the most difficult device that Foxconn has ever assembled”. Workers are assembling iPhones in two new plants they are not familiar enough with, using brand new production processes that take time to perfect. Build quality will improve over time as workers advance their skills, but only to the extent of the limitations regarding the handset’s anodized coating…

Lorraine Luk, reporting for the Journal:

“The iPhone 5 is the most difficult device that Foxconn has ever assembled. To make it light and thin, the design is very complicated,” said an official at the company who declined to be named.

Foxconn is making Apple’s newest phone at plants in Zhengzhou, central China, and in Guan Lan, in southern China. The Zhengzhou plant was set up in 2011 so it’s still pretty new to the company.

Per this executive:

It takes time to learn how to make this new device. Practice makes perfect. Our productivity has been improving day by day.

He also said Foxconn is working around the clock to address scratches on the device’s metal backplate. Foxconn reportedly “implemented a new quality check” procedure to reduce the chance of damages to the iPhone’s Unibody aluminum chassis during manufacturing.

But there are limitations as to what a sensitive coating adorning the iPhone 5 can withstand.

“It’s always hard to satisfy both aesthetic needs and practical needs,” said the executive.

Now, Foxconn’s been under tremendous pressure to meet Apple’s stringent requirements. It goes without saying that the iPhone maker is displeased as build quality has been slipping, resulting in easily scratched devices – even out-of-the-box.

A marvel of engineering the iPhone 5 may be, but it’s mostly Apple’s fault as the company demands that differences between individual devices be measured in microns. This unheard-of obsession with manufacturing has strained Foxconn, even prompting a massive riot amongst its workers who clashed with management because they felt Apple set the bar too high.

To tell you the truth, I’ve heard too many stories from too many trusted friends about the iPhone 5 scratching too easily. It blows my mind that Apple chose to go with aluminum, a material known to be “soft” to the extent that “normal” tear and wear can easily produce visible recesses on its surface.

The fact that the handset’s darkened metal alloy is anodized doesn’t help either. While anodizing produces a nice fit and finish, the layer is only skin-deep and easily peels off to reveal bare metal underneath. A much, much better solution would have been ordinary polycarbonate or Liquidmetal.

On the other hand, it all boils down to how your handle your device.

I am careful as to who gets to touch my 64GB white iPhone 4S.

Spent a fortune to buy it off-contract. Needles to say, I’m careful not to throw it on the table recklessly or pick it up in a hurry. I never rest my iPhone on bare surfaces either. Instead, I always put a magazine, a handkerchief or at least a piece of paper between the phone and the surface it’s resting upon.

I ain’t joking.

Disclosure: I don’t do cases because the iPhone is far too beautiful in my view to be concealed in a sleeve.

Maybe I suffer from a case of obsessive–compulsive disorder. Be that as it may, I’m willing to accept the diagnose if that means I’m obsessed with keeping an expensive gadget in pristine condition.

Call me naive, but I recently made a decision to hold off purchasing the iPhone 5 until early next year. I’m just shit-scared it will arrive with scuffs or scratch if I look at it the wrong way.

Joking aside, the iPhone 5 is a brand new product with insane production requirements. Manufacturing is clearly still ramping up. Demand is off the charts and won’t cool off until the iPhone 5 arrives to the promised 100 countries across 240 carriers by year’s end.

At this point, I just don’t have confidence that the iPhone 5 units coming off the assembly line in China meets all of Apple’s standards. Matter of fact, I’m pretty sure the units due in a few months time won’t be as scratch-prone as today’s devices.

What’s your angle on the iPhone 5, Foxconn and manufacturing woes?