Apple has reportedly delayed a cheaper Vision Pro headset as its suppliers are struggling with the complex design of the current $3500 AR/VR headset.

Apple reportedly delays a cheaper Vision Pro, may use mini-LED displays instead

Apple has reportedly delayed a cheaper Vision Pro headset as its suppliers are struggling with the complex design of the current $3500 AR/VR headset.

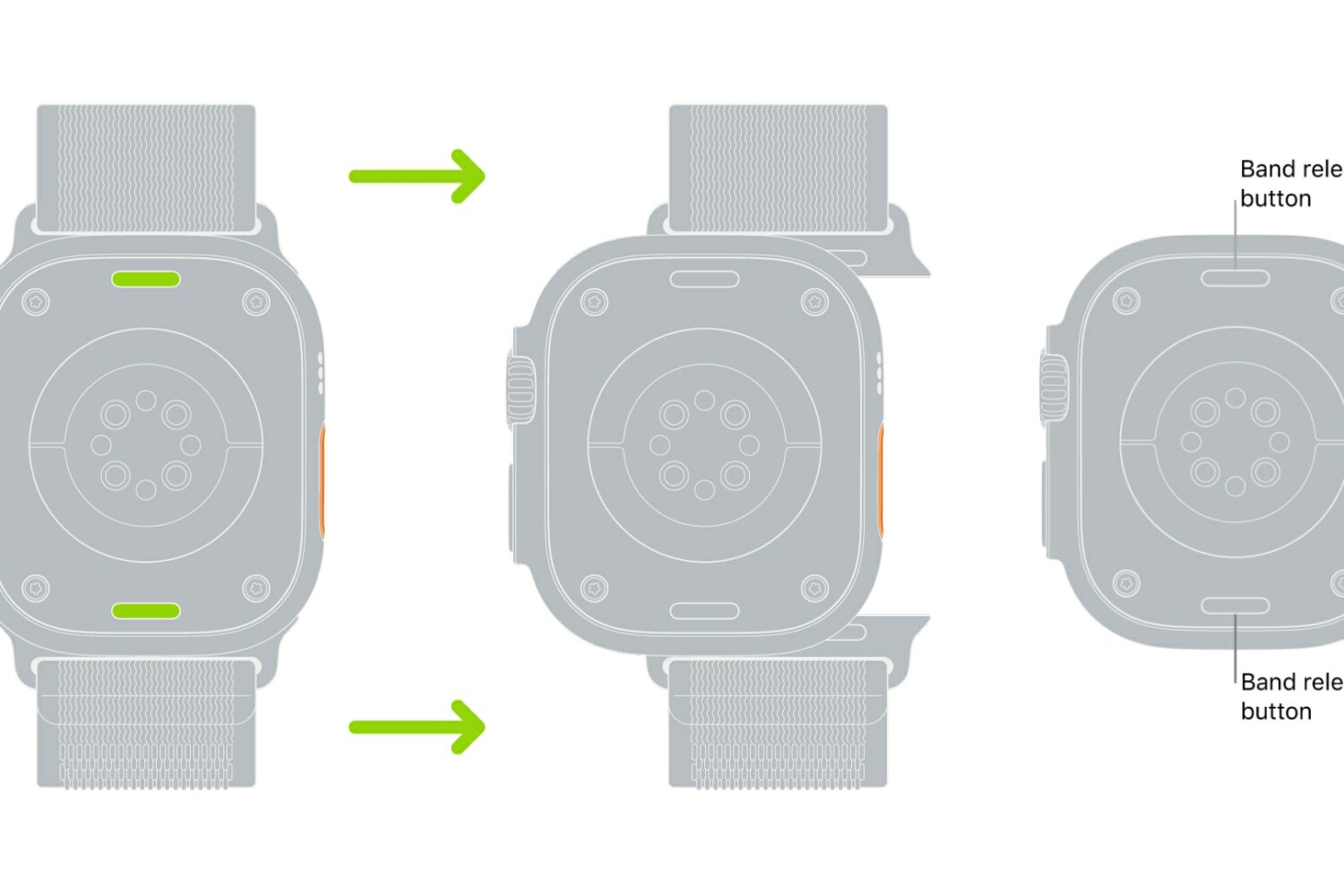

Apple Watch has popularized swapping straps thanks to its seamless band release mechanism that's much more complex to manufacture than you can ever imagine.

Apple says COVID-19 cases impacted manufacturing facilities, resulting in longer wait times for its iPhone 14 Pro and iPhone 14 Pro Max handsets.

As the pandemic continues to strain supply chains the world over, the availability of Macs, iPads and other Apple devices is dwindling in retail stores.

Apple will allegedly select the main Apple Car manufacturer by the end of 2022, with South Korean suppliers apparently already vying to provide parts.

The global chip shortage has worsened and not even Apple is immune to this industry-wide supply chain problem. According to a new report, the Cupertino company has sharply cut back on iPad production and redirected certain tablet components to the latest iPhone 13 models in order to boost handset inventory and support holiday sales.

iPhone production is taking a pretty big hit with the news that Apple might cut production targets for the latest iPhone 13 models by ten million units due to the current chip crunch.

Apple was predicted to unveil the third-generation AirPods during its iPhone 13 reveal, but that hasn't happened. Industry sources claim the earbuds have now entered mass production, but does it mean that AirPods 3 could be launching in the next few weeks?

Apple Watch Series 7 mass production should start following the iPhone 13 unveiling as suppliers have resolved manufacturing challenges caused by the device's updated design.

You may be able to buy an Apple Watch Series 7 from day one after all. Apple's suppliers have now resolved production snags and are reportedly starting volume production by month-end.

Apple Watch Series 7 won't have a blood-pressure sensor, Bloomberg claims, although that doesn't mean that a future model won't include it. Also, expect launch availability issues.

Apple's upcoming 2022 iPad Pro models will use chips built on TSMC's cutting-edge three-nanometer manufacturing process, resulting in a speed boost and lower power consumption.