Not that long ago, these three words – ‘Made in USA’ – stood out for American quality, craftsmanship and reliability. What a difference a few decades make! As everyone’s been building virtually everything in China, small wonder even Apple’s boss Tim Cook, like his predecessor Steve Jobs, suspects those manufacturing jobs won’t be coming back anytime soon. What might is (some) assembly work.

It was only recently that the nation’s tech brands began experimenting with doing final assembly domestically. Motorola, for example, is putting the final pieces of the Moto X in place at a Texas plant, previously a Nokia facility.

Apple, in the meantime, has always designed its products in California and tapped its vast network of suppliers and contract manufacturers in Taiwan and China to build its gizmos. That’s starting to change now as Apple’s next-generation Mac Pro marks the company’s return to the US in a limited manufacturing capacity.

The upcoming dream desktop is being assembled in a $100 million U.S. plant. And like Motorola’s, Apple’s facility is located in Texas. So, how does Apple build such a sophisticated and radically rethought desktop computer? Industrial designer Greg Koenig took a closer look at an eye-candy Mac Pro assembly video Apple played at yesterday’s keynote, here’s what he gleaned from it…

For starters – and as you could imagine – Apple’s assembly process for the machine is really sophisticated.

How sophisticated, you ask?

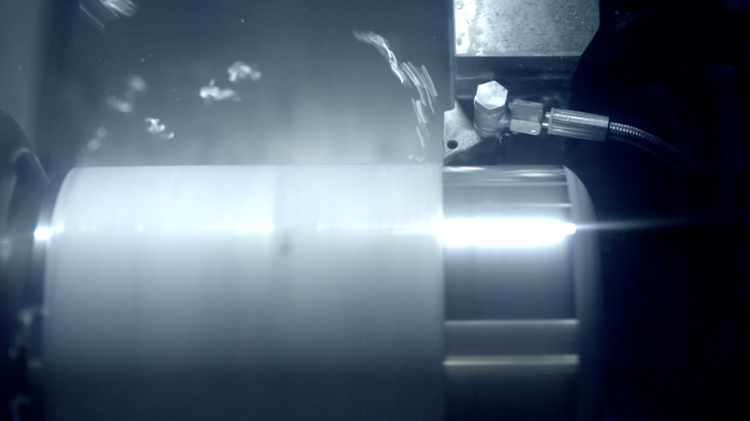

Well, consider for a moment that most metal stampings go through one or two die tools to produce the final shape. So to mass-produce the Mac Pro’s perfect cylindrical enclosure without tearing, rippling or deforming it, it must to go through a series of CNC and milling operations that progressively stretch the aluminum, until it slowely but surely begins to take the final shape of a Mac Pro.

Here, check out Apple’s ‘how it’s made’ video first.

What you just saw is so-called deep drawing process, a production technique that stems from the similar deep draw stamping process used to make everyday objects like toilet brush canisters, for example.

Koenig explains over at the AtomicDelights blog.

Deep drawing is a process that very efficiently produces a “net shape” part. Apple could have just chucked a giant hunk of aluminum in a lathe and created the same part, but that amount of metal removal is extremely inefficient.

Deep drawing efficiently creates a hunk of metal that is very close to the final shape of a Mac Pro in just a couple of operations. After that, the Mac Pro enclosure is lathe turned to clean up the surface and achieve desired tolerance, polished, placed back in a machining center to produce the I/O, power button and chamfer features and finally anodized.

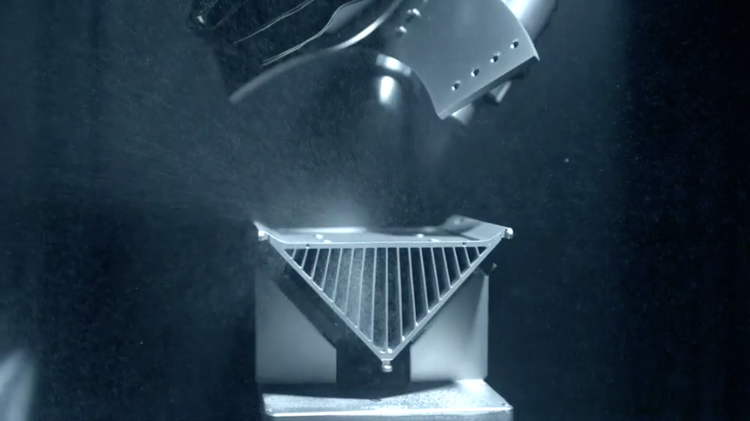

With the Mac Pro, Apple has elevated a relatively low-precision/low-tolerance process (deep draw stamping) used to make my dog’s water bowl and toilet brush canister into the creation of an aerospace grade piece of desktop jewelry.

What makes Apple’s process really unique – and this is very much true with their other precision-crafted gadgets – is that they perform their manufacturing “with remarkable precision and on a scale that is simply astonishing, using techniques typically reserved for the aerospace or medical device industries,” writes Koenig.

And this, too:

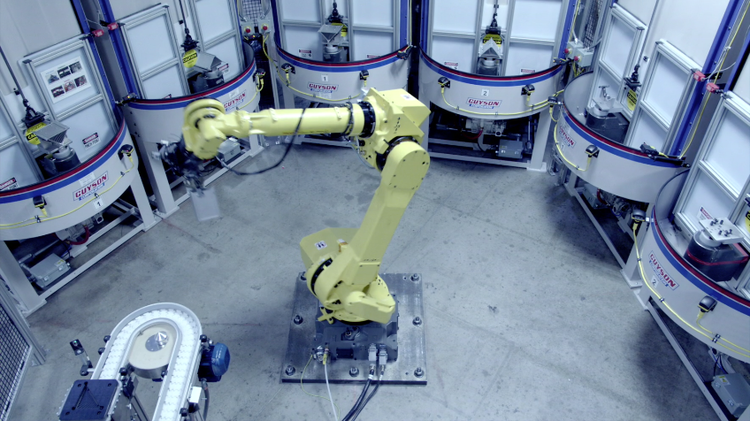

The hand assembly of the Mac Pro uses an under-table parts delivery system.

I had never seen this before and called an assembly engineer I know who said these were a new trend.

They save space by utilizing area that would otherwise be wasted, they make it easier to keep dust off the components and (most interestingly) they are more conducive to automated assembly practices when robotic tech catches up.

He goes on to call the end result that is the cylidrically-shaped Mac Pro “an aerospace grade piece of desktop jewelry” (and I concur).

Below: a bunch of Mac Pro enclosures being prepped for the anodization process.

According to Tim Cook himself, the $100 million dollar factory in Texas relies on equipment produced in Kentucky and Michigan. Also, the final assembly uses components made in Illinois and Florida.

If you could afford dropping $3,000 on a pro desktop, would you buy this new Mac Pro?

It’s a dream machine, no question about it.

Too bad I haven’t started saving for it last year ago or something.

Apple has said the new Mac Pro will start shipping in December, starting at $2,999 for the entry-level configuration with an Intel Xeon 3.7GHz quad-core chip, 12GB of DRAM, 256GB of snappy PCIe flash storage and dual-workstation AMD FirePro graphics.

There will be a more powerful $3,999 model and customers will be able to customize their own configuration through the online Apple Store.